Manufacturers

Springs, clips, washers and pins

Associated Spring is a worldwide leader in the design, manufacture and sale of springs formed in 1857. They are spring suppliers and spring stockists, supplying thousands of spring parts to industry. Besides conventional compression and extension springs the range of springs AsSpec supplies include many different kinds of spring types as disc springs, die springs, finger, wave and curved spring washers, conical springs, spring-loaded devices, tool clips and spring pins too, etc.

Each spring and each component are designed precisely and made from highest quality raw materials to English or German standards using the highest quality steels. That’s why the quality of components is assured so high class service of Associated Spring is available at any time.

Unlike many spring manufacturers AsSpec guarantees the spring load instead of the pitch and turns.

Biotek Kft. is currently offering a wide range of springs approx. 2900 different types from stock in which compression spring, extension springs, torsion springs, disc springs, die springs, retaining pins, spring pins and tool clips are also available.

Catalogue of AsSpec springs and elements and ISO Die Springs is downloadable in PDF format.

Compression springs

- ’A’ metric type - all dimensions and forces to DIN 2095 (Grade 2)

- ’B’ inch type

- Extension springs

- ’A’ metric type - all dimensions and forces to DIN 2095 (Grade 2)

- ’B’ inch type

- Compression / extension springs (metre length)

- Finger spring washers

- Wave spring washers

- Curved spring washers

- Disc spring - according to DIN 2093

- Torsion springs

- Constant-force springs

- Heavy-duty compression die springs

- Die springs – manufactured to ISO specification

- Interlock Garter springs

- Conical compression springs

- Spring-loaded devices

- Pins & Rings

- Tool clips

- Spring pin

Pop Blind rivets

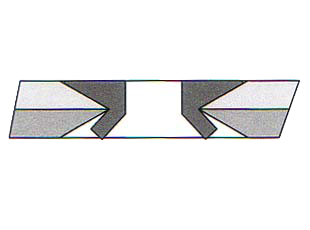

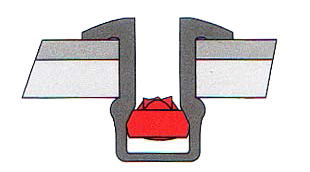

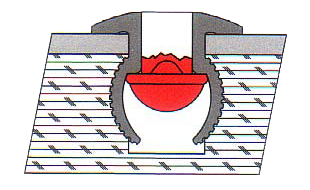

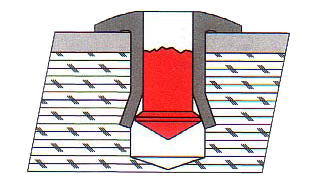

Blind rivets are generally used to fix together two or more metal sheets. Installation of blind rivets happens into appropriate sized pre-drilled holes using rivet tools. Besides widespread mass produced dome headed and open ended blind rivets the original POP® manufacturer has many different types of rivets from different materials, different designs with special features for demanding applications.

Mechanical strength and features of a rivet not only depends on its material but the full design and manufacturing process are also important. Rivets have to be chosen to correspond to application’s requirements because different rivet designs behave different way, have different advantages and disadvantages, different features:

- Mandrel head retention

- Solid wall

- Secondary expansion

- Degree of sealing

- Hole filling

- Rattle resistance

- Multi grip capability

- Claim capability

Blind rivet types:

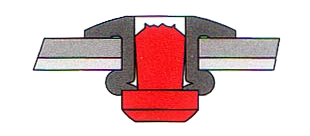

Break stem open

General purpose open rivet available in wide range of materials and head styles. Suitable for applications with low load bearing requirements.

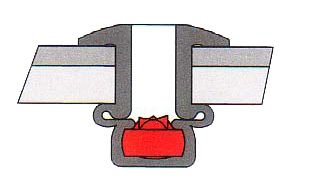

FSR (flush setting rivet)

Open rivet that sets flush on both sides of the application when set into a double countersunk hole. This space saving rivet offers near zero protrusion and eliminates loose mandrels.

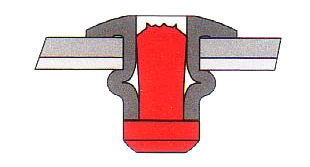

Closed end

Designed with a completely closed body, this rivet is ideal for applications that need to be water/pressure tight or where mandrel retention is paramount.

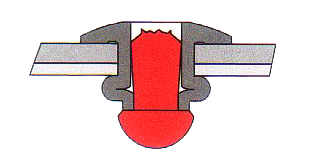

LSR (load spreading rivet)

Load spreading characteristics make this rivet ideal for use in vulnerable, friable and the softest of material.

MGR (multi-grip rivet)

The Multi-Grip rivet is designed to accommodate a wider grip range than other rivets allowing for lower inventory levels. Also provides good, rattle free, joint construction even in irregular holes.

Vgrip

Vgrip

Highly aesthetic, Multi-Grip rivet with positively retained mandrel head. Also offers excellent claim properties, a large blind side for increased tensile strength and grooved stem for optimum tool jaw life.

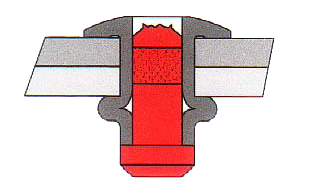

Peel

Ideal for joining softer and more brittle materials such as plastics, rubber, wood, GFRP or laminates.

T-rivet

T-rivet

The T-Rivet offers all the features of a peel rivet with the added benefit of pull-up. Improved shear strength is also achieved due to mandrel head retention after setting.

F-series

F series provides excellent hole fill for superior vibration resistance combined with a locked, rattle free mandrel that results in great joint construction.

HS (high strength)

The POP® rivet with the strength of an M6 Bolt also provides excellent claim properties, a positively retained mandrel head and wide blind side expansion.

HR (high retention)

Exceptional pull-up capability and increased blind side expansion give the perfect combination for overcoming air gaps whilst spreading the load during setting. Excellent mandrel retention and rattle resistance after setting.

Grooved

Aluminium rivet for fixing into wood and other soft/fibrous base materials. Suitable for use in blind non-through holes.

STR

This steel rivet has a peeling body ideal for use in wood and providing high resistance to pull out loads and mandrel head retention.

TVD

This unique closed end stainless steel range provides additional support to assemblies where weak or thin blind side materials are present.

Let us know the required material, hole size, grip or grip range, the features from above list rivets need to be corresponded and if there are shear and tensile strength requirements. Our colleagues will help you to choose most convenient rivet type for your application.

You can find full range of rivets and technical data are in POP rivets catalogue is available for download in PDF format from our website.

Plastic fasteners and components

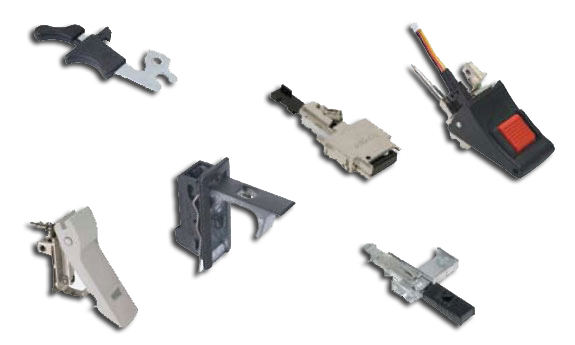

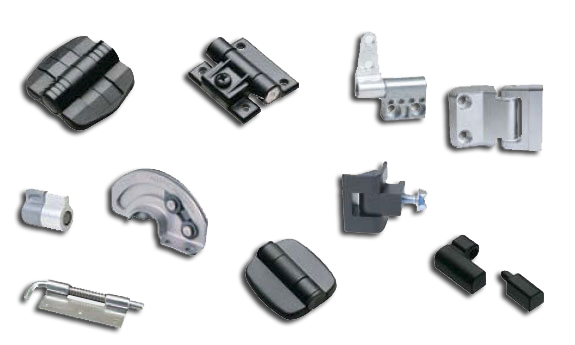

Industrial latches, hinges, fasteners

Main features of Southco products that most of them has extra function beside its basic functions. For example, a latch is not only a latch but handle too, or pull the door to gasket to increase degree of sealing, or a hinge is not only for the moving of flap but able to position it at certain opening angles or in any angle.

Southco products are used in many industrial areas, e.g. in electronics, telecommunications, IT, automotive, agricultural machinery, construction machinery, single purpose machinery, industrial storage systems, ventilation equipments, shipbuilding, bus manufacturing, rail transport vehicles, etc.

Southco product categories:

- Electronic access solutions

- Compression latches

- Cam latches and swinghandles

- Push-to-close latches

- Cam locks and lock cores

- Draw latches

- Multi-point latching systems

- DZUS quarter-turn fasteners and fast lead screws

- LOCKWELL quick-release pins and quick access fasteners

- Captive screws

- Inject-eject mechanisms

- Hinges and position control devices

- Inserts, standoffs and assembly fasteners

- Handles and pulls

Southco was founded in 1899 has been producing latches, hinges and fasteners for industry since 1945 with continuously expanding product range. The company has ISO 9001, QS 9000 and ISO 14000 quality certificates.

Biotek Kft has been offering Southco products in Hungary since 1992. Products can be seen and tried out physically in our showroom to give more idea for interested customers and our colleagues can provide information on the functions of related products helping to select the most suited solution for your application. Wide range of Southco latches, hinges, pulls and fasteners are available from our stock.

Push-on fasteners

Baker and Finnemore has manufactured precision pressings for many years supplying the likes of the lock industry with strip formed lock springs, the electronics industry with heat-sinks and heat-sink clips, stainless steel grab rings for easy fix plumbing fittings, retaining clips for infinite applications, bearing retainers for the automotive industry and many more.

We also manufacture non-standard disc springs and belleville washers, waved (curved) washers, knob clips, corner clips and cable clips. Precision pressings can be manufactured from spring steel, stainless steel, brass, aluminium, beryllium copper phosphor bronze etc.

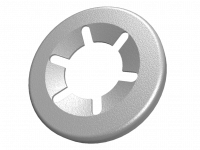

The Starlocks® push on fasteners are manufactured from finest quality high carbon steel and are specially heat treated to ensure secure holding quality. Starlocks® fasteners simply push on to the shaft to give an instant fix and grip, thus eliminating costly threading and grooving operations. Once fixed in position, the Starlocks® push-on fasteners are so secure that they cannot be removed without destruction.

The majority of our Starlocks® push-on fastener range can be supplied assembled with a cap to conceal the fixing and enhancing the appearance.

Starlocks® Push on Fasteners are available with or without a decorative cap. The standard dome and standard deep axle caps are manufactured from Stainless steel whilst the extra deep axle cap is manufacture from steel and electro zinc plated. To satisfy customer demands the caps can be made from other metals dependent on material specification and volume required. The caps hide the end of the axle and the Starlock push on fastener when assembled to provide a cosmetic appearance.

Captivated Starlock push-on fasteners are available in three distinct styles Dome Axle Cap, Deep Axle Cap and Extra Deep Axle Cap.

Starlocks® Push On Fasteners Advantages:

- RoHS compliant.

- Suitable for plain shafts.

- Can replace circlips, cotterpins etc.

- No need for screw threads.

- Permanent fixing.

- Eliminates tolerance stacking.

- Low cost assembly solution

.

. - Can be automated.

- Dedicated engineering resource.

- Pressing capacity up to 60 tonnes.

- In house tool design.

- In house Toolroom.

- Sample development.

- In house heat treatment & finishing.

- Manufactured in the United Kingdom.

Special Starlocks® Capped & Uncapped (Axle Caps, Dome Caps, Deep Axle Caps)

- To suit non standard shaft sizes / shapes. (Rectangular, Square, Triangular, etc).

- Sample development service.

- Alternative materials & finishes.

Materials

Carbon Spring Steel and Stainless Steel.

Surface Finish

Starlock® Push-On Fasteners can be supplied in Bronze and Varnish, Delta Protekt or in Mechanical Zinc plated finishes and certain sizes are available in Stainless Steel.

Starlocks® Mechanical Zinc Plated

Mechanical Zinc Plating is universally recognised, as the answer to ensuring products have no hydrogen embrittlement.

Starlock® Bronze & Varnish

There are two ranges of standard spring steel Starlocks®: one range for imperial sizes and the other for metric. For identification purposes a colour code is used to denote the ranges. The imperial spring steel Starlocks are coloured Blue and the metric is coloured Bronze. The Starlocks are then given a thin varnish coating to provide a high level of finish. This finish will not protect against corrosion but is adequate for the protection of the Starlocks® in most dry environments.

There are two ranges of standard spring steel Starlocks®: one range for imperial sizes and the other for metric. For identification purposes a colour code is used to denote the ranges. The imperial spring steel Starlocks are coloured Blue and the metric is coloured Bronze. The Starlocks are then given a thin varnish coating to provide a high level of finish. This finish will not protect against corrosion but is adequate for the protection of the Starlocks® in most dry environments.

Starlocks® Stainless Steel Push On Fasteners

There are many applications where the Starlocks® requires a high level of corrosion resistance or it is unsuitable to use a plated finish. A limited range of Starlocks® have been manufactured from austenitic stainless steel and are available to provide the answer.

Applications

External fixing washers: for use not only on precision machined shafts but also on tubes, cast parts, plastic shafts and studs. The Starlocks® Push-On Fasteners are pushed on to the shaft causing the prongs to grip the shaft tightly, thus locking the washers in place.

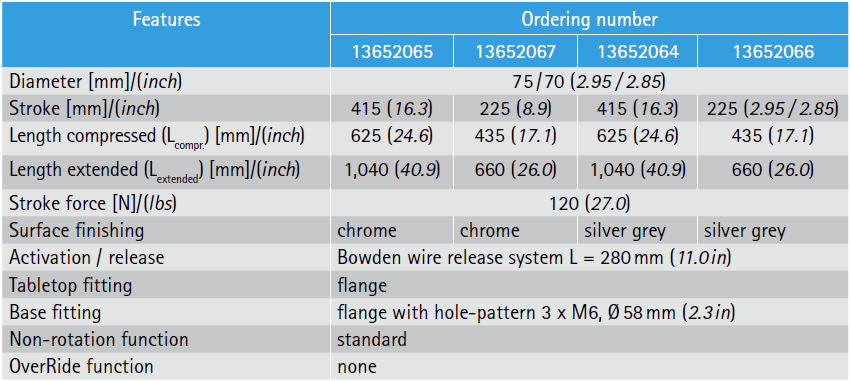

Gas springs

Gas spring is a hydro-pneumatic energy storage machine element is widely used in many industries. In any applications where some mass should be held or movements should be eased off because of ergonomic reasons, usage of gas springs provides practical solution. For this reason the possible application areas of gas springs are limited only by the borders of engineers’ creativity.

Gas spring is a hydro-pneumatic energy storage machine element is widely used in many industries. In any applications where some mass should be held or movements should be eased off because of ergonomic reasons, usage of gas springs provides practical solution. For this reason the possible application areas of gas springs are limited only by the borders of engineers’ creativity.

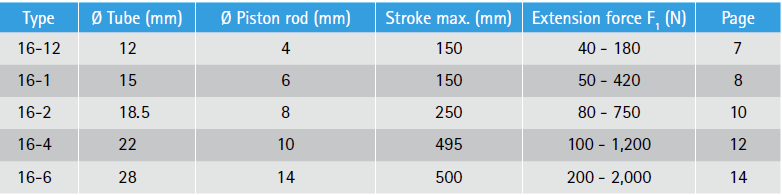

Suspa Liftline gas springs have reproducible high quality. The table below provides a quick overview of Suspa gas spring range but more detailed information is findable in the catalogue.

Click on the link of Suspa Liftline catalogue of gas springs to find or download it in PDF format. The range this catalogue contains is always available in the stock of Suspa we can provide you filled to required force with short delivery time. Of course, customized special gas springs also can be developed and produced for request.

Main application areas:

- Automotive (buses, cars, caravans, trailers, livestock carrier vehicles, etc.)

- General engineering and single purpose machines (flaps, covers, mechanisms, etc.)

- Furniture industry (kitchen cabinets, beds, fold-away beds, etc.)

- Logistics (storage-transport boxes, containers, etc.)

- Security (emergency opening of relief doors, air-outlets, etc.)

- ther applications (solarium, ease off electromotor of lift arms, etc.)

Insert technology for plastics

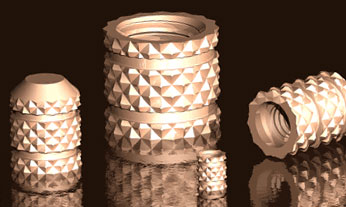

Tappex Thread Inserts Ltd has been manufacturing inserts since 1956. With more than 50 years’ experience, it sees itself a company who takes part in to solve fastening problems rather than simply be a fastener supplier. Due to continuous development Tappex’s range of inserts for plastic includes more than 20 standard variations from M1.6 to M12 for use in all grades of thermoplastic, thermoset, structural foam and composite materials.

General application area of Tappex brass inserts in plastic, but certain types can be used in aluminium and some metal alloys. Threaded inserts provide load bearing thread in softer materials where normal screws can destroy the joint after more turning in and out. Using Tappex internal threaded inserts you can apply higher stud tightening torque than using metric screw directly in the plastic.

You can install post-mould inserts effectively with installation equipments of Tappex exist.

Tappex insert types:

- Self-tapping inserts (Trisert®, Trisert-3®, Foamsert®)

- Press-fit inserts (Multisert®, Microbarb®)

- Insert for moulding in (HiMould®)

- Specials (anti-creep spacers, male inserts, etc.)

On the following pages for further information about Tappex insert technology:

Tappex inserts

Tappex installation equipment

Range of inserts

Trisert® - self-tapping inserts

The Trisert self-tapping threaded insert was developed to post-mould production process. The Trisert design use external thread to be tapped into plastic to provide balanced cutting and reduced installation torque. As the installation tools pick up Trisert by its internal thread to install, every insert is therefore automatically checked for the existence of a good thread. FlexiArm machine provides fast and efficient cold installation for self-tapping inserts.

Trisert inserts can be used in thermoplastic and thermoset grades including the latest engineering plastic alloys.

- Double ended (M2-M10, in three lengths)

- SReduced headed (M3-M8)

- Regular headed (M2.5-M10, in two lengths

Trisert-3® - self-tapping inserts

This is the latest development of inserts are made from case hardened steel, grade 303 or grade 316 stainless steel. Trisert-3 was developed to critical application circumstances which unsuitable for brass inserts, can be used in hard plastics and in some metal alloys. Its design is based on the reduced headed version of Trisert insert.

- Reduced headed (M3-M8, in two lengths, three materials)

Foamsert® - self-tapping inserts

The Foamsert is a special version of the Trisert for foam materials, laminated chipboards, medium density fibre board and certain types of glass reinforced plastics. Installation method of Foamsert is the same as Trisert settling.

- Double ended (M2.5-M8)

- Reduced headed (M3-M8)

Multisert® - press-fit inserts

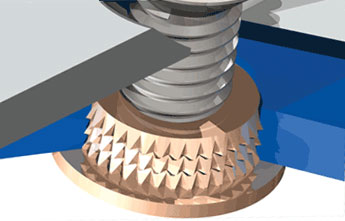

The Multisert press-fit threaded insert was developed to post-mould installation process. Barb form on its external surface makes the insert suitable for different installation methods into thermoplastics. Flexible base materials allow the easy and fast cold press-fit installation. For improved performance, it can be press fitted with heat insertion or ultrasonic, which maximize the fill of molten plastic around the barbs. Harder or flame retardant materials require heat or ultrasonic assistance in any event.

- Unheaded (M2-M12, in two lengths)

- Single thickness head (M2-M8, in two lengths and head diameters)

- Double thickness head (M1,6-M10, in two lengths and head diameters)

Microbarb® - press-fit inserts

The Microbarb is the special version of Multisert with larger head and barb diameter to provide increased bearing surface. It was developed to pull through applications in thin section thermoplastic materials. Microbarb has the same installation method as Multisert insert has.

- Large headed (M2-M10)

HiMould® - inserts for mould-in

The HiMould range of brass threaded inserts has been designed for moulding-in during the cycle of the moulding machine.

HiMould inserts do not require threaded pins located inside the mould tool but rapidly located onto appropriate plain pins giving higher productivity and reducing tool down time. Unique design of HiMould insert still give guaranteed flash free threads. It is widely used in all types of thermoplastic and thermoset plastic mouldings.

- Type 'A' blind ended (M3-M6)

- Type 'B' open ended (M2-M12)

- Type 'C' blind ended with counter-bore in the open end (M2-M10)

Special Tappex inserts

- Anti-creep spacers

They are designed to provide reinforced clearance holes for bolts to pass through a plastic moulding, and thus allow metal-to-metal clamping forces to be applied to an assembly without over-stressing the plastic.

- Male inserts

They are available based on the same body design and installation features of the female equivalent. Thus the basic forms of Trisert, Multisert or HiMould, can be produced in Unheaded and Headed versions with the same Short, Regular and Long body lengths as the relevant female insert, with a defined stud length.

- Imperial range

They use the external features of the nearest metric equivalent product. Popular imperial sizes are available from stock.

- Specials

Where a standard product does not exactly meet the requirements of a given application then Tappex may already have stock of a special variation that is suitable. For special requirements there is a possibility to produce customized inserts.

For larger order quantities inserts can often be produced as ‘specials’ to the customer’s requirements. For availability, please contact us. Non stocked special Tappex inserts are only available on request of significant quantities. Please, contact us with your special requirement with detailed specification.

Product range and technical data can be found in Tappex general catalogue in Hungarian is available for download in PDF format from our website. Tappex general catalogue does not contain Trisert-3 self-tapping inserts.

Trisert-3 catalogue is available for download in PDF format from our website.

Riveting systems

POP® brand is very well known today by almost every people works in industry. One-sided fastening method of blind rivet was patented in 1916 by a British aircraft manufacturer and Tucker Fasteners was the chosen for serial production because of his expertise. Demands for blind rivets highly increased during the Second World War made it known and widespread after it in every industrial segment.

Types of POP® products have been expanded not only increasing the range of rivets but also to offer blind river nuts and rapid fastening systems. Giving full technological support for customers, pneumatic and hand operated installation tools are available.

POP product groups:

Tucker Fasteners is the part of the market-leader Emhart Teknologies company is at the forefront in development and trying to react for customers needs to offer solution with new, innovative products. Biotek Kft distributes products of original POP® manufacturer to be at the front in solution oriented riveting technology.

Self-clinching fasteners

Self-clinching fasteners for sheet metals

The most widespread usage of PEM® fasteners is installing into metal sheets. For your application you can find the appropriate type of nuts, studs, standoffs, panel fasteners are made from different materials with different finishes.

General PEM® fasteners:

- self-clinching nuts

- nuts (S, SS, H, CLS, CLSS, SP)

- nut for thin sheet (SMPS)

- flush nut (F)

- self-locking nuts (LAS, LAC, SL, HNL, LK, LKS, LKA, PL, PLC, CFN)

- floating nuts (AS, AC, LAS, LAC, F10)

- blind nuts (B, BS)

- miniature nuts (FE, FEO, FEX, FEOX, U, UL)

self-clinching studs

self-clinching studs

- threaded studs (FH, FHA, FHS, FH4)

- threaded studs for thin sheet (TFH, TFHS)

- threaded studs for close-to-edge (FHL, FHLS)

- high-strength studs (HFH, HFHS, HFHB, HFE)

- concealed head threaded stud to blind hole (CHA, CHC, CFHA, CFHC)

self-clinching standoffs

self-clinching standoffs

- thru-hole threaded standoffs (SO, SOA, SOS, SO4)

- blind threaded standoffs (BSO, BSOA, BSOS, BSO4)

- standoffs for ultra thin sheets (TSO, TSOS, TSOA)

- standoffs for close-to-edge (DSO, DSOS)

- „Snap-Top” standoffs (SSA, SSC, SSS)

- concealed head standoffs to blind hole (CSS, CSOS)

- self-clinching pilot pins (TPS, TPS4)

self-clinching panel fasteners (PFHV, PF10, PFC2, PFS2, PFC2P, PFC4, PF11, PF11M, PF11PM, PF12, PF12M, PF30, PF31, PF32, PF50, PF60, SCB, SCBJ)

self-clinching panel fasteners (PFHV, PF10, PFC2, PFS2, PFC2P, PFC4, PF11, PF11M, PF11PM, PF12, PF12M, PF30, PF31, PF32, PF50, PF60, SCB, SCBJ)

For technical details find pages of PEM® catalogue.

Self-clinching fasteners for stainless steel sheets

Contrary to the beliefs, self-clinching fasteners made from stainless steel material are not surely suitable for installing into stainless steel metal sheets. For these applications PEM® range contains heat-treated stainless steel self-clinching fasteners.

PEM® fasteners for stainless steel sheets:

- self-clinching nut (SP)

- self-clinching threaded stud (FH4)

- self-clinching pilot pin (TPS4)

- self-clinching panel fastener (PFC4)

- self-clinching standoffs (SO4, BSO4)

- self-clinching SpotFast fastener (SFP)

Broaching fasteners for P.C. boards

Developing electronics industry made a demand to new generation fasteners are suitable to be installed into non metallic base materials. As a result PEM® designed a fastener range can be set into plastic and/or P.C. boards.

PEM® fasteners for PCB sheets:

- broaching nuts (KF2, KFS2, KPS6)

- broaching threaded stud (KFH)

- broaching standoffs (KFE, KFSE, KFB3)

- broaching „Snap-Top” standoff (KSSB)

- ReelFast SMT standoffs (SMTSO)

- grounding standoffs (SOSG, SOAG)

- broaching panel fastener (PFK)

Special self-clinching fasteners

Besides fasteners for general fastening usage the PEM® innovations offer self-clinching fasteners for specific functions also.

PEM® fasteners for special functions:

- self-clinching „Keyhole” fasteners

- self-clinching plunger assembly, spring loaded (PTL2, PSL2)

- „R’Angle” right angle clinch fasteners (RAA, RAS)

- self-clinching SpotFast fasteners (SF, SFP, SFW)

- self-clinching cable tie mount hardware (TD, TDO)

- flare-in nuts (RHB, HHB, RMHB)

- projection weld nuts (WN, WNS)

For detailed geometric and required hole dimensions can be found in PEM® catalogue is available for download in PDF format from our website.

Self-clinching technology

A PennEngineering & Manufacturing Corp. (PEM® Fastening Systems) company was founded in 1942 to produce his own invention was a revolutionary new product: the self-clinching fastener. This easy-to-install fastening solution provides load-carrying threads in metal sheets too thin to be tapped.

Following industrial demands range of fasteners also widened. Today, nuts, threaded studs, standoffs and hundreds of fastening elements are offered for industries such as electronics, aerospace, automotive, machinery, agricultural machinery, furniture and telecommunications industry.

Biotek Kft started to distribute PEM® fasteners to self-clinch in 1994 and since then wide range of fasteners is offered from stock. In our showroom, our staff can demonstrate the operation, functions and advantages of PemSerter presses were developed to install PEM® fasteners. Feel free to contact us with questions about pressing process and special requirements.

Most of the fasteners are manufactured by PennEnginereeng Fastening Technologies are RoHS (2002/95/EU) compliant.

Parts are generally so-called self-clinching fasteners can be pressed into a ductile workpiece to cold-flow base material. Thanks to the shape design of self-clinching element during the installation base material cold-flows around each segments of the fastener resulting good strength against tensional and torsional loads occur. Main requirements of self-clinching process are fasteners always have to be harder than base material and sheet has to be ductile enough.

Advantages:

- Fewer parts required. Losable screws, nuts, washers, spring washers are no longer necessary to final assembly.

- Less assembly steps required. Fasteners are installed during part manufacturing to allow decreasing steps of final assembly.

- Final result is shorter assembly time. Fewer parts and less assembly steps causing shorter assembly time which reduce the operating prime cost.

Self-clinching fasteners

PEMSERTER® installation

Bonding fasteners

BigHead termékek típusai

Standard machine elements

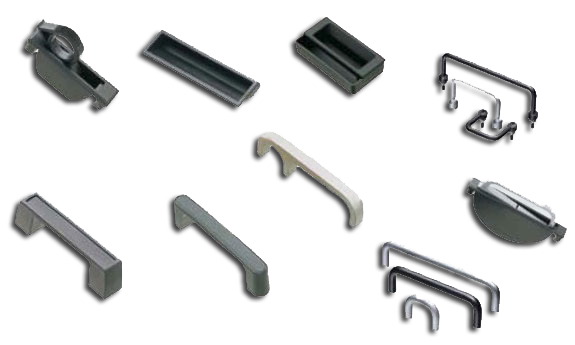

Elesa+Ganter's machine elements provide solutions for design engineers, manufacturers and maintenance to many application areas.

Products are developed to original form and unique design following strict ergonomic considerations to meet both the aesthetic appearance with user-friendly usage and function criteria. As a result, these products have been selected many times by most prestigious international industrial design juries (Die Gute Industrieform - Hannover, Design Center - Stuttgart, Compass d'Oro - Milan).

Elesa+Ganter company mainly focus on the market of the machinery design, engineering machinery and its recurring parts, so it offers a wide range of sizes and types of products, such as the handwheels, crank handles, knobs, wing screws, hinges, rotary indicators, bases, clamps, indexing plungers, accessories for hydraulic systems, level indicators, cups, etc.

Click on the link to find additional information about the range of Elesa+Ganter products.

Product range contains high performance items for special applications beside the standard machine elements for general purpose.

High level technical support of design engineers is very important for our supplier, hence available CAD design files are constantly expanded on Elesa+Ganter website. After a brief registration, 3D models in STEP format and 2D drawings in DXF format can be downloaded.

Elesa and Otto Ganter have been co-operating for more than 30 years to create market synergies and to develop new products. In many countries they joined together in partnership under the trademark Elesa+Ganter, to offer the widest range of standard machine elements and components available on the market. For Elesa+Ganter, quality is an absolute value. A philosophy that involves all company processes: from engineering to production and from logistics to marketing. As a result of our quality assurance, ELESA and GANTER were among the first companies being certified according to ISO 9001.

Machine elements groups

Operating elements

- Spoked handwheels

- Solid handwheels

- Arm handwheels

- Crank handles

Clamping knobs

- Lobe knobs

- Star knobs

- Grip knobs

- Wing knobs

Clamping levers

- Adjustable handles

- Lever handles

U-handles

- Bridge and pull handles

- Safety handles

- Flush pull handles

- Tubular handles

Fixed, revolving and fold-away handles

- T-handles

- Ball knobs

- Fixed handles

- Revolving handles

- Fold-away handles

Control elements

- Control knobs

- Control levers

- Adjustable slide units

Rotary controls

- Gravity indicators

- Positive drive indicators

- Handwheels / handknobs with indicator

- Direct drive indicators

Indexing elements

- Indexing plungers

- Cam action indexing plungers

- Side thrust pins

- Spring plungers

- Lock pins

Machine elements

- Grub screws and thrust pads

- T-nuts

- Rings and washers

- Ball transfer units

- Cam locking levers

- Clamps

Joints

- Universal joints

- Ball joints

- Angled ball joints

Levelling elements

- Plastic bases

- Metal bases

- End caps

- Flexible automation components

- Connecting clamps and angles

Hinges, latches

- Plastic hinges

- Metal hinges

- Locks

- Latches with handles

- Latches with key

Toggle, power and hook clamps

- Toggle clamps

- Clamping bolts

- Power clamps

- Hook clamps

Accessories for hydraulic systems

- Plugs

- Breather caps

- Oil level indicators

- Column level indicators

Tube clamp connectors

- Clamp connectors

- Linear actuators

- Round, rectangular tubing

Castors and wheels

- Rubber, polyurethane and monolithic wheels

- Swivel and fixed bracket

- With or without brake

Magnets

Haeger® insertion machines

Haeger is a market leader with nearly 40 years of experience in the development and manufacture of fastener driving machines. The primary goals in the design of Haeger machines are safe operation and productivity. The unique, patented double safety system ensures safe operation with both active and non-conductive workpieces.

Developed to increase production speed, the T.I.S. (Turret Insertion System), also known as the rotating anvil system, allows up to four different clamping elements to be inserted in a single work phase by gripping the workpiece once. The automatic bottom tool change unit of the 824 One Touch four-feeder machine serves the same purpose, with automatic tool change without operator assistance.

Haeger, through the modular design of its machines and its wide range of products, aims to enable the widest range of sheet metal working companies to find the model that best suits the size, profile, production volume, financial situation and future plans of their company. From entry-level manual feed models, all of which can be upgraded with an automatic feed system, to multi-feeder models, it is easy to find the ideal fastener inserting machine. An additional advantage of Haeger machines is that, in addition to fastener insertion, they also support direct material joining (Tox, BTM) without fasteners.

Haeger, in 2018, became part of the PennEngineering group, a market leader in the development and manufacture of press-fit.

Cable managenent, plastic fasteners

H eyco company was founded in 1926 and joined to PennEngineering Group in 2016. Heyco offers solutions for cable routing and cable management application area with his more than 90 years experience. Heyco range we offer contains simple cable bushings, stain relief bushing, cable clamps, different kinds of hole plugs but plastic catches and strikers, well nuts, drive fasteners, etc. are also available.

eyco company was founded in 1926 and joined to PennEngineering Group in 2016. Heyco offers solutions for cable routing and cable management application area with his more than 90 years experience. Heyco range we offer contains simple cable bushings, stain relief bushing, cable clamps, different kinds of hole plugs but plastic catches and strikers, well nuts, drive fasteners, etc. are also available.

The constant high quality of Heyco products are guaranteed because their quality system are compliant and certified to ISO 9001.

Heyco product groups:

- Cable management

- Grommets and bushings

- Plugs

- Circuit board hardware

- Plastic rivets

- Bumpers and feet

- Fan accessories

- Insulators

- Cable ties and accessories

Structural fastening systems

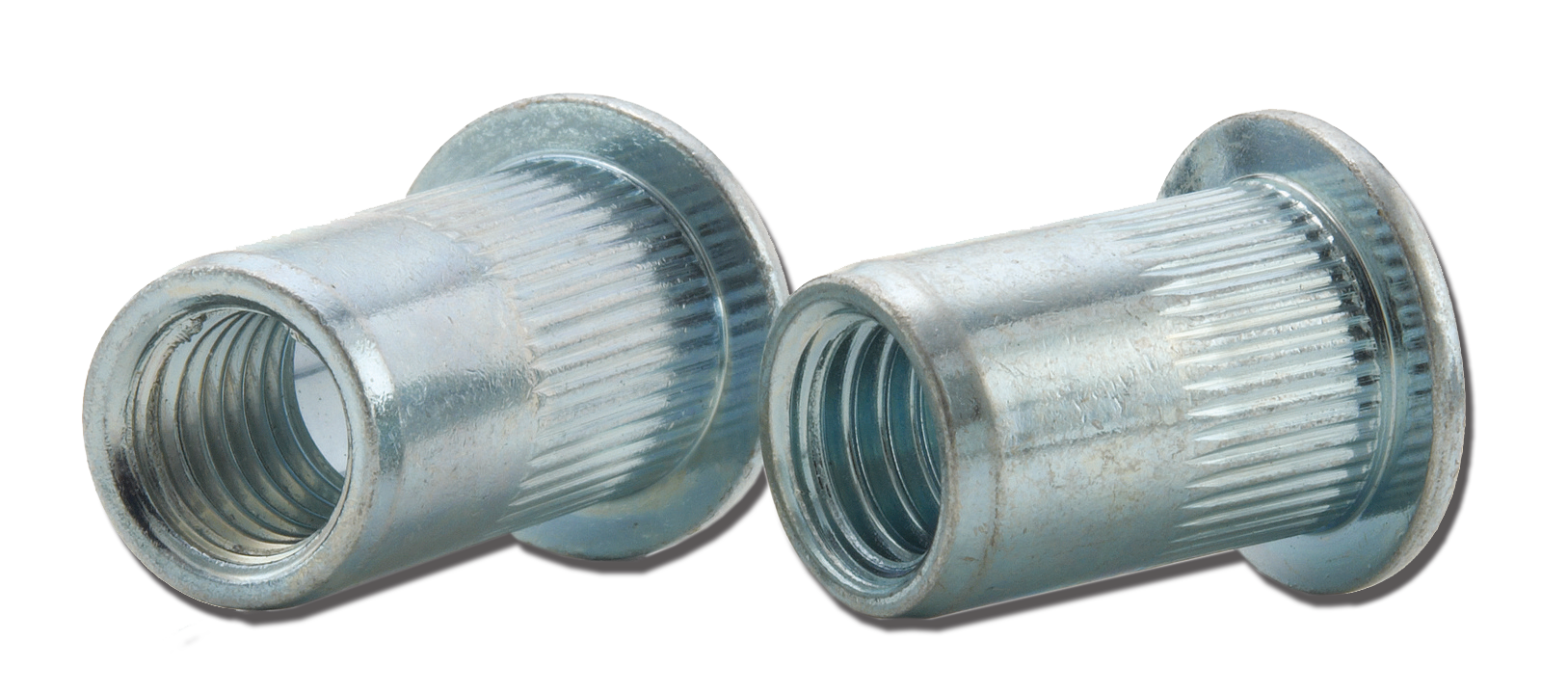

Blind rivet nuts

Company Dejond was formed in 1901 in Belgium has been producing Tubtara blind rivet nuts since 1954. In the middle of 60s Dejond was the first in Europe who started to change manufacturing process of rivet nuts to cold forming from screw machining. Quality of product is ensured by ISO 9001 certification.

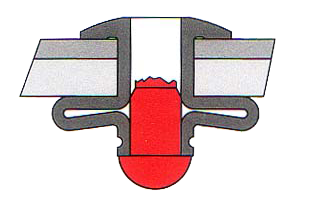

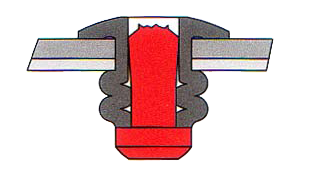

Tubtara® blind rivet nut ensures load bearing thread in thin sheets or in application where there is no or little access at the rear side. It not only used as a nut for a screw, but also to clench separate sheets together therefore acting as a river as well. Tubtara® has to be placed into appropriate sized hole and install with rivet nut tool. Mandrel of the tool pulls the insert lengthwise which cause body to expand on the underside of the workpiece to clench it tightly.

Due to the continuous development the range of Tubtara rivet nuts grow continuously, new designs, new sizes new materials appear. Unique type of Tubtara rivet nuts are made from 316 stainless steel material which can be used in highly corrosive environment.

Benefits:

- Simple blind (one sided) installation

- Provides strong secured thread in a thin sheet

- Fast assembly time

- Avoids damaging the surface

- No deformation of the workpiece

Sizes:

- M3 - M12

Grip range:

- 0.5 - 8.0mm

Body design:

- round, splined round, hexagonal, semi-hexagonal shanks

- open ended, closed ended

- flat, countersunk, low profile heads

Materials:

- aluminium

- steel, Zinktop finish (yellow chromated also available on request)

- stainless steel 304

- stainless steel 316

Blind rivet nuts can be used in wide range of industrial segments and applications such as food industry, pharmaceutical and chemical industry, electronic equipments, medical equipments, telecommunication, metal furniture, automotive industry, ships and boats, aerospace, mass transit vehicles, lighting equipments, power plants, etc.

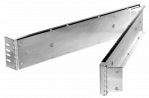

Telescopic slide types

Due to high production quality standards ball guidance and elements of slide fits together with high guidance accuracy giving smooth, precise and light moving during catalogue specified lifecycle.

Due to high production quality standards ball guidance and elements of slide fits together with high guidance accuracy giving smooth, precise and light moving during catalogue specified lifecycle.

Besides easy handling, as main requirement, almost all of slides have one or more special features which make Accuride slides much more than a simple, functionless guide. Applying Accuride slides you can improve space utilization and due to certain features can provide easy, safe access for repairing or maintenance of your product.

Special features Optionally, additional accessories, mounting brackets are available for certain slide types to make mounting easy.

You can find detailed data sheets and technical support of slide selection in Accuride catalogue in English is available to download in PDF format from our website.

Gas springs, dampers, lift systems

Suspa GmbH who was founded in 1951 has become one of the largest gas spring and lift system manufacturers in the world. Advanced manufacturing and quality control system ensures constant high quality level of products. Thanks to continuous R&D and engineering works more highly sophisticated new product ranges have been developed and are offered for high-end applications beside conventional gas springs.

Suspa product groups:

For more information about the product groups click onto links above.

For the fast and efficient service to partners there is a so-called “Quick-Ship” program of gas springs and lift systems is a range for general use can be reach from stock in short lead time for small amount of required quantities. This range is contained by Suspa catalogues is available for download from our website. If this range does not meet the customer’s requirement, customized application-specific products can be developed.

Bearing in mind the quality and the environment, Suspa is certified to ISO/TS 16949 automotive, ISO 9001 quality management and ISO 14001 environmental management standards.

Telescopic ball bearing slides

Accuride has been at the forefront in the design and manufacture of telescopic slides and movement systems since 1962. Continuous development with first-class manufacturing and continuous quality control are guarantee the constant high quality and offer expanding product range for customer needs.

Product groups of Accuride:

These products help better space utilization and access. Additional features of slides offer a solution for wide area of applications to move drawers, trays and units while using lifts TV or monitor can be hidden in furniture easily.

Main application areas:

- Industrial machinery and storage cabinets

- Electronic units and testing equipment

- ATM and gaming machines, cash-registers

- Telecommunication racks

- Emergency vehicles and trucks

- Trains, aircraft, ships, boats

- Furniture, office furniture, desks

All fully operational production facility of Accuride are certified to ISO9001, with European plants also achieving the ISO14001 Environmental Standard and the ISO TS16949 standard for automotive production.

Accuride®

Accuride

Elesa + Ganter®

Bolt securing system

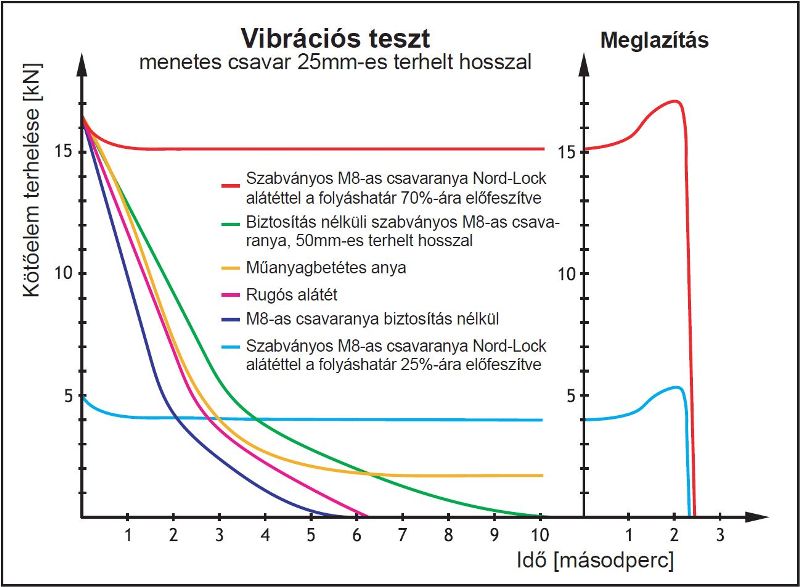

Applying appropriate stud torque Nord-Lock® bolt securing system guarantees stable tensile load in the screw stem even in case of strong loosening effects such as vibrations, dynamic loads, etc. The product itself is a pair of washers to provide wedge-locking according to standard DIN 25201. Nord-Lock® washers have to be placed directly between the surface and bonding unit without using any other washers.

When the screws and / or the nut is tightened, radial teeth on the external surface of washer grip and seat into the mating surface locking the two half-pair of washers in place and internal cams with rise are engaged. After tightening, movement to loosening direction is allowed only across the face of the cams.

Nord-Lock uses tension instead of friction, they come pre-assembled in pairs. On the inner side of washers have cams with rise which is bigger than the pitch of the bolt. On the outer opposing side radial teeth take place which functionally fix the washers to surface during tightening. Thanks to all of these features even slight rotation occurs in loosening direction, washers try to move on the cams resulting additional tension created in the bolt to make the joint self-locking. Every loosening attempt is eliminated by wedge action of inner cams.

Nord-Lock washers provide secured joint in case of vibrational circumstances and impulsive dynamic loads as well.

Tests substantiate the benefits of Nord-Lock® bolt securing system benefits:

- provide safe bolted connection even regular dynamic loads occur

- lubricant does not have an effect on tightness of joint

- resists the loosening effects caused by vibrations

- screw joint can be installed easily and fast

- after dismantling Nord-Lock washers are reusable some time

- self-locking effect is independent from tightening torque

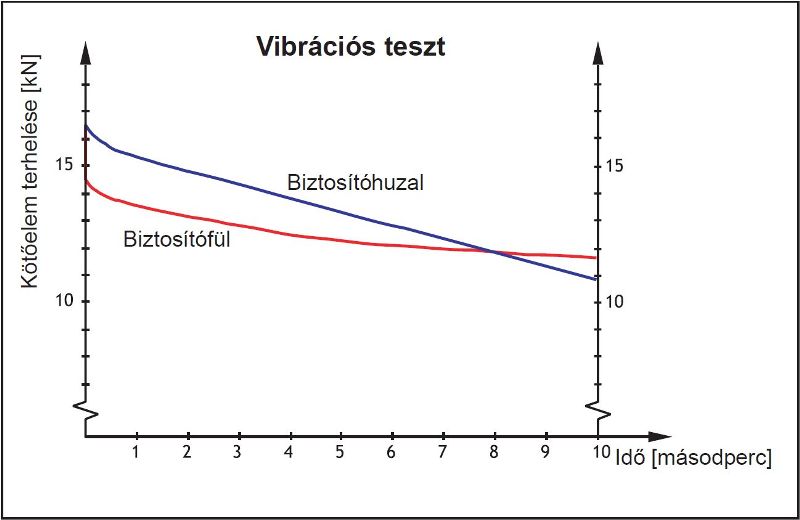

Efficiency of screw connection can be inspected and demonstrated by Junker vibration test equipment and the corresponding computer program. The Junker test investigate behaviour of standard M8 screw joint with dynamic load in case of usage of different types of screw securing methods such as Nord-Lock bolt securing, slit ring, claw washer, nylon inserted nut.

Junker vibration test curves:

Nord-Lock sizes:

- Delta-protect coated steel (ELV, RoHS compliance): M3-M130

- stainless steel (SS 2343): M3-M80

- normal and increased external diameter

For further information about full range, technical data and allowed assembly methods find Nord-Lock Hungarian catalogue is available for download in PDF format from our site.

Installation equipments

FlexiArm®

The FlexiArm has been designed for the rapid cold installation of the Tappex Trisert, Trisert-3 and Foamsert in high volumes.

The FlexiArm has been designed for the rapid cold installation of the Tappex Trisert, Trisert-3 and Foamsert in high volumes.

The installation machine is a pneumatic screwdriver on a pantograph arm mechanism. The screwdriver can be specified with automatic or manual reverse torque-clutch control, with different RPM, depending on the size of the insert and the receiving material.

Its size allows it to be installed alongside the respective moulding machine, so that inserts can be fitted during the waiting time of a typical mould cycle. It is available with one, two or three arms to suit most multi-task assembly requirements. A range of production drivers is available to provide an accurate method of installing the inserts at various heights and positions in the moulding.

Rapid installation tray can be used for easier installation of certain M2-M6 inserts.

Hand tools

For installation of self-tapping inserts in low-volume when investment to FlexiArm device is not paying, Tappex hand tools are recommended to use.

The series 031 hand tools are suitable for installation of Trisert, Trisert-3 and Foamsert from M2.5 to M10 size threaded inserts.

Heat Inserter

For harder grades of thermoplastic, press fitting of Tappex Multisert and Microbarb needs to be assisted by either heating the insert to prevent the plastic becoming stressed which can lead to cracking over time, particularly in thin sections or in long thin bosses.

For harder grades of thermoplastic, press fitting of Tappex Multisert and Microbarb needs to be assisted by either heating the insert to prevent the plastic becoming stressed which can lead to cracking over time, particularly in thin sections or in long thin bosses.

Tappex Heat Inserter has rugged construction and a variable feed-back temperature control to suit virtually all grades of thermoplastic and also a speed control to prevent the operator overriding the correct insertion cycle time. An indicator light illuminates as soon as the insert is fully installed.

It has an output of 400w and comes complete with three interchangeable heat tips, for different sizes but other heat tips are available to order.

In case you are interested in Tappex installation equipments or tools for your Tappex inserts, please, contact us.

PEMSERTER® installation

PEMSERTER® presses have been developed to install PEM® self-clinching fasteners. Manual or automatic feed tooling sets are exist for almost all PEM® made fasteners to press in with which you can settle self-clinching parts effectively and constant high quality on PEMSERTER® presses. There are simple pneumatic press for manual feed, hydro-pneumatic and servo electromechanical presses for manual and automatic feed and fastener feeding system for in-die clinching so you can easily find the most suited to your company’s production volume from the range of installation equipments

PEMSERTER® Series 4 press

PEMSERTER® Series 4 is a pneumatic manual feed press with lockable storage cabinet-stand, resettable cycle counter, laser pointer, and with reliable integral point-of-operation safety system, 457mm throat depth and maximum 53.4 kN ram force which allow insertion into steel up to M10 fastener sizes, to softer material up to M12. Easy to use with minimal maintenance requirements features the press, so essential accessory for sheet metal worker companies produces in small- and medium serial.

PEMSERTER® Series 4 is a pneumatic manual feed press with lockable storage cabinet-stand, resettable cycle counter, laser pointer, and with reliable integral point-of-operation safety system, 457mm throat depth and maximum 53.4 kN ram force which allow insertion into steel up to M10 fastener sizes, to softer material up to M12. Easy to use with minimal maintenance requirements features the press, so essential accessory for sheet metal worker companies produces in small- and medium serial.

Optionally available QX4 manual turret tool system allows installing 4 different types of fastener with one grab of workpiece.

Benefits:

- integral point-of-operation safety

- tooling exchange within 2 minutes

- 457mm throat depth

- parts tray holder

- 650 cycle/hour insertion (depending on operator and workpiece)

- QX4 manual turret tool system as option

- CE certificate

Specifications:

Ram force: max. 53.4kN

System type: pneumatic / lever

Air requirement: 6-7bar, 2,79 liter/ciklus

Height (on stand): 1676mm

Width: 660mm

Depth: 940mm

Weight (w. stand): 372kg

Special features

Front disconnect

Disconnect allows simple connect/disconnect for a slide member from slide assembly by releasing an internal lever.

If maintenance requires quick and easy access to the area beyond drawers this feature is beneficial by simple removing and remounting drawers avoiding the time-consuming screwdriver usage.

Lock-in / Lock-out

Locks hold the slide either fully closed or open and a lever must be actuated to move the slide.

This function is proposed in applications where movement of slide by inertia of drawer unit resulting random opening and closing is not permitted for safety reasons. In case of drawers in vehicles (trains, buses, etc.), battery trays, large and heavy to move units can be involuntary moved causing accidents, usage of this feature is strongly encouraged.

Hold-in / Hold-out

It keeps the slide open or closed until extra force is applied.

Hold feature is suggested where locking feature is not necessary but slight horizontal deviations of floor can cause opening or closing of drawers. Popular feature of tools, personal stuff and parts storage cabinets, drawers in industrial environment where levelling difficult to resolve even in movable units.

Self-close (SC, HDSC)

Self-close slides include a spring attachment designed to close the slide near to ‘in’ position and prevent bounce back. SC is normal type while heavy-duty version (HDSC) provides increased self-closing force.

This feature is beneficial for drawers, which include end-all-closed is an important requirement, such as in cabinet where a drawer without complete closure doesn’t allow opening another one. It’s useful function of mobile drawer storage as well.

Easy close (EC)

It is a dampened self-close slows the closing action for controlled and smooth operation. This feature avoids a separate damper or slam inhibitory element integration, therefore usage is widespread in high-end furniture, kitchen furniture and office furniture.

Touch release (TR, HDTR)

Touch release slides open and close with pressure to the front of slide. TR is normal type while heavy-duty version (HDTR) provides increased stay-closed option.

This function allows eliminating usage of handle or pull of drawers presenting aesthetic outside appearance. Usage is popular in high-end furniture, kitchen furniture, office furniture, hidden drawers case.

Cam drawer adjust

Cam drawer adjust allows minute adjustment to the drawer front for easy alignment by eccentric screw.

It’s useful feature of multi-drawer cabinets where subsequent fine adjustment of drawers may be required because of possible manufacturing inaccuracies.

Standard feature on 2132 and 3832 series slides.

Shock blocks

Shock blocks are hardened steel pins that provide an interference fit between the slide members to minimize the amplification of vibration and reduce the damaging effects of shock in the closed position. Standard feature on 0522 series slides.

Recommended slide feature of large mass units on vehicle (such as truck battery tray) and beneficial to use in any vibration environments.

High performing items

Stainless steel products

The high corrosion resistance of stainless steel has made it into one of the most demanded materials in many sectors of industry. Elesa+Ganter’s product range includes a wide assortment of rustproof products, spread over all product groups. It covers both all-stainless steel standard elements (INOX) as well as stainless steel and plastic composites. The materials used are AISI303, AISI304 and AISI316, resistant to rust, acid and heat depending on alloys.

Designed for:

- Food industry

- Chemical industry

- Medical engineering

- Demanding climatic conditions and atmospheres

- Aggressive substances

Clean-line / White against the dirt

Industrial handles, lobe and knurled knobs in RAL 9002 white colour with glossy finish to make cleaning operations easier. AISI 303 stainless steel metal inserts in compliance with the most rigorous sanitary laws. It has compact shape and lack of cavities to avoid any deposit of dirt, dust and machining residues.

Designed for:

- Medical and hospital equipment

- Operating rooms

- Hospital fittings

Antimicrobial protection

These products stop the deposit of any undesired organisms such as microbes, bacteria, mildew and fungi which are the major causes of unpleasant odours, discoloration, degradation and the formation of biofilm on surfaces and prevent them from reproducing. A special technopolymer including antimicrobial additives - a mixture of silver ions on an inorganic ceramic base - chemical free without any antibiotic drugs or pesticides which may be released on the operator’s hands.

Designed for:

- Medical and hospital equipment

- Disability aid

- Machines for the food processing and pharmaceutical industry

- Equipment for catering services

Soft-touch products for a safer grip

These new elements have been developed for use on machinery and equipment requiring frequent tightening, or for applications subject to severe stress. The major characteristics of "SOFT" products are to ensure a safer and more stable ergonomic grip and to improve the comfort of the operator's hand, increasing adherence to the element and absorbing vibrations even in unfavourable environmental conditions such as humidity, aridity, heat, cold and grease.

Designed for:

- Disability aids

- High-precision instruments

- Fitness machines

- Gardening and unfavourable climatic conditions

Antistatic action

The special conductive technopolymer (ESD-C Electrostatic Discharge Conductive) prevents the transfer of electrostatic discharge between bodies with different electric potential. The printed mark ESD-C on the surface of every single element identifies the particular antistatic feature according to EN 100015/1 and IEC 61340-5-1.

Designed for:

- Assembly lines for electronical components

- ESD-Protected Area (EPA)

Oil level sight glasses for special applications

Elesa+Ganter’s extensive range of oil level sight glasses also provides solutions for highly demanding requirements, for instance high temperatures, high pressure loads or aggressive substances. The most recent development is an ATEX sight glass for use in explosion hazard atmospheres.

Designed for:

- Industrial products such as gears, used in applications where the components must comply with ATEX guidelines

Associated Spring

POP-Nut threaded inserts

POP-Nut is the perfect solution for providing high quality, load bearing threads in thin metal sheets, tubing and in other one sided access places. Threaded inserts have to be placed into appropriate sized hole and install with rivet nut tool. Mandrel of the tool pulls the insert lengthwise which cause body to expand on the underside of the workpiece and fix the insert stable in the carrying material.

Benefits:

- Can be installed from one side

- Provides load bearing thread in thin sheets

- Fast assembly time

- Not damage the surface

- Not deform the workpiece

Sizes:

- M3 l- M12

Body design:

- round, splined round, hexagonal, semi-hexagonal shanks

- open ended, closed ended

- flat, countersunk, low profile heads

Materials:

- aluminium

- steel

- 302 series stainless steel

POP-Nut blind rivet nuts are made of various combinations of body design, dimensions and materials. For detailed information click on the link of POP-Nut threaded insert systems catalogue is available for download in PDF format from our website.

Pop-Nut threaded inserts can be used in wide range of industrial segments and applications such as food industry, pharmaceutical and chemical industry, electronic equipments, medical equipments, telecommunication, metal furniture, automotive industry, ships and boats, aerospace, mass transit vehicles, lighting equipments, power plants, etc.

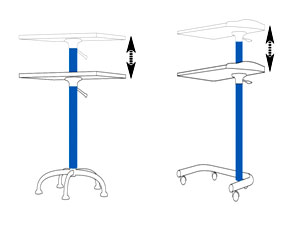

Lockable gas springs

Lockable gas spring is a hydro-pneumatic energy storage machine element which can be locked in any position of its stroke. Its usage can be ideal solution for any application where the advantage of a gas spring needs to be combined with locking feature.

Lockable gas spring is a hydro-pneumatic energy storage machine element which can be locked in any position of its stroke. Its usage can be ideal solution for any application where the advantage of a gas spring needs to be combined with locking feature.

Depending upon the behaviour of locking elastic, rigid to extension and rigid to compression types can be differentiated:

- Elastic locking Varilock types are EL1, EL2. Their usage is suggested if cushioning effect is required in locked position. With elastic locking sudden loads cab be avoided or at least dampened.

- Rigid locking Varilock types to extension are HY1 and HY3, rigid locking Varilock types to compression are HY4, HY6. Their usage is suggested if a cushioning effect should be avoided.

With high precision valve mechanisms of Suspa lockable gas springs special functions are available. These intelligent features can add value to end product into gas spring is built in increasing the quality of application and making more competitive:

EasySwitch

EasySwitch

With this module, users control the valve ‘digitally’ alternating between the closed and permanently open position and back again.

TimeReset

TimeReset

Detects whether the application into gas spring was built in is loaded by weight or not. If it is not loaded, Varilock returns to the starting position within a custom definied period of time.

- OverRide

It enables to users to move application in the extension direction without activation of release mechanism. Finishing the moving application remains in the position where it was left. Its usage is popular in hospital beds, over-bed tables and in one leg table systems. This function is offered as option in Varistand product of Suspa.

- CushyRelease

Actuation force of lockable gas springs is directly proportional to the extension force which can cause uncomfortable handling in low and high extension forces. With this function you can optimize the actuation force for ergonomic handling.

Main application areas:

- Furniture industry

- Healthcare equipments, rehabilitation

- Fitness, wellness

- Public transport vehicles

- Automotive

- Other applications

We can help you to develop the appropriate lockable gas spring for your application cooperating with application engineering of Suspa which requires minimum order quantities. For after sales we have limited possibilities to sell lockable gas springs because in many cases products are developed to contracted partners who have the only right to purchase products directly from Suspa. In these cases, please, contact the manufacturer of end-product in which you found the gas spring you need.

Southco product categories

Electronic access solutions

Recognizing the growing need for electronic access Southco provides electro-mechanical latches and accessories for. Electro-mechanical latch or keeper is connectable to keypad, electronic key system, RFID proximity reader or remote control receiver. Concealed types of latches increase vandal resistance and allow aesthetic appearance.

Compression latches

Compression latches

Common feature of compression latches that during closure the pawl of latch is moving to pull door to the frame resulting gasket becomes compressed. This provides more efficient sealing, dampened vibration and lower noise level. Compression latches was designed cannot be opened accidentally by vibrations. Sealed latch versions meet the standards of NEMA and IP.

Cam latches and swinghandles

Cam latches are the most widespread latch type which allows a simple and quick latching by right angle turning. Combination of key operated, tool operated, hand operated and wing style latches with fix or adjustable grip offers wide range to find the appropriate solution for your application.

Push-to-close latches

Main feature of push-to-close latches is simple slam closing. When door is slammed with enough impetus latch close automatically, no secondary steps required for latching. Mode of opening is depends on the latch type, it could happen with usage of key, handle of latch, electronic access or simply to pull out the door. There are concealed push-to-close latches too.

Cam locks and lock cores

Cam locks are small, cost effective latch solutions with large grip range. Certain types have removable lock plug to create possibility for different key alike, different key system and master key system can be ordered. Some compression latches, cam latches and push-to-close latches allows to use these lock core systems also.

Draw latches

Draw latches

Southco draw latches are used to fix firmly together panels in-line or perpendicular position. Over-centre, under-centre, rotary, concealed and flexible types are made from steel, stainless steel, rubber or plastic contains versions with or without key locking, padlocking providing fix or flexible lock.

Multi-point latching systems

Multi-point latching systems

Multi-point latching systems provide a convenient solution for large door spans with a single user touch point operating multiple latch point. Over-centre mechanisms provide the ultimate in consistent compression along the entire edge of the enclosure door.

DZUS quarter-turn fasteners and fast lead screws

DZUS quarter-turn fasteners and fast lead screws

Dzus quarter-turn fasteners provide cost-efficiency and space-save for closure. Difficult-to-loose hardware exists in plenty of length, with different head design and more kinds of receptacle. Usage of fast lead screws are beneficial if frequent access is required or in case of heavy vibration environments.

LOCKWELL quick-release pins and fasteners

LOCKWELL quick-release pins and fasteners

Lockwell pins cannot be removed from place until trigger mechanism is released by actuator button is pressed. Beside versions with trigger mechanism can be found models with simple push-to-install pull-to-remove operation and spring loaded positioning plunger for mounting to sheet.

Captive screws

Captive screws

Main feature of captive screw that after installation into sheet they cannot be fall out. This advantage is beneficial in electronic application where a loosened screw could cause shortcut or other mess in the end-product. There are snap-in, press-in, flare-in and floating styles with metric or unified threads ans different head designs.

Inject-eject mechanisms

Inject-eject mechanisms

Most of inject-eject mechanisms are PICMG compliant and allow easy fixing and releasing of P.C. boards. Versions are available to meet regulation of ATCA, AMC and cPCI.

Hinges and position control devices

Hinges and position control devices

Southco hinges are highly engineered products with ergonomic and aesthetic design. Most of them have extra features, there are concealed, removable and detent types, position control hinges with constant symmetric, asymmetric or adjustable torque, bi-stable and miniature hinges.

Inserts, standoffs and assembly fasteners

Inserts, standoffs and assembly fasteners

Southco MonoSet and Duosert inserts are used to replace standard cage nuts in IT style rack enclosure providing more flexibility for reconfiguration. Easy to install plastic spacers and fasteners, removable push style rivets can be also found in the range.

Handles and pulls

Handles and pulls

Range of Southco handles contains highly aesthetic fix and foldaway grab handles, pull knobs, concealed pulls and flush pulls.

Hydraulic dampers

Hydraulic damper is an energy converter machine element which converts the kinetic energy of moving into thermal energy and thereby reducing shocks or vibration. Its usage can be ideal solution where high oscillation amplitudes need to be reduced or damage could be caused by planned or accidental high impact load have to be avoided. Their usage is popular in drop-down cabinet doors to prevent to fall.

Hydraulic damper is an energy converter machine element which converts the kinetic energy of moving into thermal energy and thereby reducing shocks or vibration. Its usage can be ideal solution where high oscillation amplitudes need to be reduced or damage could be caused by planned or accidental high impact load have to be avoided. Their usage is popular in drop-down cabinet doors to prevent to fall.

Main application areas:

- Automotive

- General engineering

- Furniture

- White goods

- Other applications

We can help you to develop the appropriate damper for your application cooperating with application engineering of Suspa which requires minimum order quantities. For after sales we have limited possibilities to sell dampers because in many cases products are developed to contracted partners who have the only right to purchase products directly from Suspa. In these cases, please, contact the manufacturer of end-product in which you found the damper you need.

TV lift & further products

TV lift (DBLIFT-0127)

TV-lift is an electro-mechanical lift mechanism to move up and down LCD or plasma TVs. Using the product televisions can be aesthetically hides into furniture when they are not watched. The operation of lift mechanism is handled by remote control.

Main features:

Main features:

- Load rating up to 54kg

- Lifting travel 864mm

- Accommodates most TVs up to 50” (diagonal measurement) and up to 85cm tall

- Raises to fully extended position in 15 seconds

- Pre-wired and pre-mounted to backboard for easy installation

- TV mounting brackets as option

- 2 remote controllers

- Built in auto-reverse safety feature

- CE approved components

- Fixing hardware includedmaximális teherbírás 54 kg

Monitor lift (DBLIFT-0019)

Monitor lift is an easy operable push to open mechanical lift developed to hide LCD monitors and small LCD TVs (max.6, 5kg) into furniture.

Monitor lift is an easy operable push to open mechanical lift developed to hide LCD monitors and small LCD TVs (max.6, 5kg) into furniture.

Usage is ideal in multi-purpose tables if space requirements or aesthetical reasons need to hide screens into desk. (e.g. in libraries, conference rooms, educational institutions, banks, shops, homes, etc.).

Main features:

- Push to open and close mechanical lift, it does not require electricity

- Suitable for screens weighing 2,5-6,5 kg, up to 22” (diagonal measurement) and up to 450mm high

- Lifting travel 538mm

- Swivel +/- 112.5°

- Raises to fully extended position in under 2 seconds

- Wire management and cable control kit included

- Fixing hardware included

- Damper and weights control movement. Adding or removing counterweights movement can be refined to the monitor's weight. The package includes one weight pack.

- RoHS compliance

- Available accessories:

- weight packs (10pcs of 110g weight)

- weight bracket for more than 2 packs

- fixed VESA bracket

- 18° tilt VESA bracket

CPU holders

With CPU holders the computer is held off the floor, well away from feet, dust and static and yet is easy to reach. Ideal for height adjusting desk systems, CPU moves with the desk top and prevents cable stretching. It can be retrofit to any table.

With CPU holders the computer is held off the floor, well away from feet, dust and static and yet is easy to reach. Ideal for height adjusting desk systems, CPU moves with the desk top and prevents cable stretching. It can be retrofit to any table.

Main features:

- Straps hold most shapes and sizes of CPU up to 34kg in weight and 163cm perimeter

- Fix and swivel versions

- Soft gripper feet hold the CPU firmly

- Vertical CPU mounting standard, horizontal mounting with optional adapter plate34kg súlyig és 163cm kerületű számítógépházig használható.

Cable carriers

With cable carrier usage you can prevent the accidental cable injury or disconnection when you pull drawer out with electrical unit.

POP-Bolt rapid fastening system

POP Bolt™ is a rapid setting, removable and re-useable fastening system. Delivering the speed of riveting combined with the flexibility of a nut and bolt, POP Bolt™ is ideal for applications that require a high strength fastener that facilitates servicing.

Two main parts of POP Bolt™ system is a threaded stud with mandrel can break off and a collar can be formed. During the installation jaws of POP-Bolt setting tool pulls the mandrel and push the collar in one time which clamps fastened material together. After it cold-forms the outer surface of collar to hexagon shape and gets flow its inner surface onto the thread of bolt creating inner thread within collar. Finally mandrel breaks off at crimp. Result is a serviceable, mechanical joint with a consistent clamp force.

Besides collar can be formed into removable hexagon nut Secureset collar provides safer joint. Its rounded form offers excellent tamper resistance and can be removed with a reverse spiral flutted socket. Additional benefits of Secureset are improved vibration resistance and a higher tensile yield.

POP Bolt head styles:

- hexagon washer head

- slotted truss head

- special head styles

POP Bolt materials:

- 8.8 steel

- A2 stainless steel

POP Bolt™ Twinfix has been developed specifically for the transport sector. The Twinfix carrier is designed to aid the fastening of buckles and rollers to truck curtains. The Twinfix allows for servicing and can be used in conjunction with Secureset to give a tamper resistant joint.

For detailed information about product range find POP Bolt™ catalogue is available for download in PDF format from our website.

PEM®

POP

Lift systems

Varistand – Height adjustment with gas spring

This system is an elegant height adjustable table column with a concealed lockable gas spring inside. Varistand column is a ready-to-install product, easy to assemble into the base with 50mm #3 Morse taper and onto the tabletop through 12 holes.

The main application areas are one-legged tables, bar tables, exhibition furniture, pulpits, etc.

Specifications:

- Extended length max.1065mm, stroke max.450mm (shorter version is possible)

- 70N or more (max.400N) extension force

- Chrome plated as standard, RAL colours powder-coating are available

- Lever, button or foot release

- OverRide function is available (raising without activating the release)

Click to the link, to download Varistand datasheet.

Table with Varistand is available in our showroom to see and try. In case of question please contact us.

Movotec – Hydraulic lift system

Movotec is an ergonomic height-adjustment system for all kinds of tables and machinery with large loads. Bolt-on system can be retrofit to existing table with minimal effort and corner leg system can be built directly into 45 size aluminium profile system.

The main application areas are workstations of production lines, rapid conversion of conveyor lines, massage tables, assembly desks, etc.

Specifications:

- Bolt-on and corner leg version

- Maximum loads up to 450kg depending on types

- Adjustment ranges of 150-400mm depending on types

- Available with hand crank or electric motor operated pumps

- Can be fit into aluminium profile systems

- Complete systems with 4 legs

You can find further information in datasheet of Movotec system is available for download in PDF format from our website. Movotec system is available in our showroom to see and try. In case of question please contact us.

ELS3 – Electronic lift system

ELS3 system is an electro-mechanical-driven lifting column with control units was mainly developed for high-end office furniture. Keeping ergonomics in mind the system offers precision height adjustment for sit to stand workplace application.

The main application areas are office furniture, pulpits and multi-functional workstations.

Specifications:

- Square leg profiles, standard and upside-down styles

- maximum load is 50kg/leg

- 2 leg system with synchronized lifting

- 570mm compressed length, 650mm lifting stroke, 35mm/s adjustment speed

- Basic hand switch, programmable hand switch or remote controlled operation

- In gray colour as standard

You can find further information in datasheet of ELS3 system is available for download in PDF format from our website. In case of question please contact us.

POP installation tools

Suspa

About

Eurofix srl is a leading fastening systems manufacturer and wholesaler.

Our production includes:

- quick lock washers

- u-nuts

- threaded chimney nuts

- cage nuts

- compression rings

- spring clips and

- spring fasteners.

Production available in carbon steel and stainless steel.

Tappex

Elesa + Ganter®

Eurofix®

Hinges and locking devices

Pinet Industrie company, managed by the same family for the past 6 generations, manufactures products for industrial applications.

Pinet Industrie is one of European's leading designer and manufacturers of hinges and locking systems, standard or custom-made.

Product categories:

- hinges

- latching systems

- handles

- accessories

Haeger®

Sugatsune

Sugatsune based in 1930 Japan has been manufacturing metal parts meets highest quality expectations.

Their broad range includes hinges, hinge mechanisms, handles and other unique items for doors, drawers, storage compartments specialized for industrial and architectural applications.

Sugatsune is one of the leading manufacturers of metal hardware. Their wide variety of high quality products covers diverse fields from residential to office furniture, architectural to industrial parts and even disaster prevention.

In 2020, Sugatsune Kogyo celebrated its 90 year anniversary.

The name Sugatsune and the LAMP brand have long been associated with Quality, Innovation and Service.

Sugatsune has a long tradition of manufacturing and distributing only the highest quality products, exports to 80 different countries around the world, has over 510 employees, 17 offices worldwide, more than 20,000 different unique items, all manufactured by Sugatsune or produced for them exclusively.

Products

- friction hinge and damper hinge solutions

- hinge mechanisms

- handles

- accessories

Heyco®

Nord-Lock®

PEM®

Pinet®

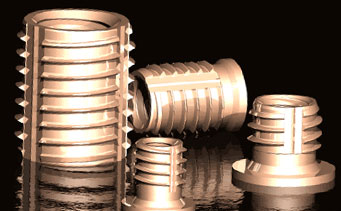

SEEGER® rings

We would like to inform you that our range has been extended with SEEGER® products, which, in addition to the classic standard Seeger inner and outer rings and fitting tools, also includes a number of other spring-loaded locking elements.

We would like to inform you that our range has been extended with SEEGER® products, which, in addition to the classic standard Seeger inner and outer rings and fitting tools, also includes a number of other spring-loaded locking elements.

Main product types:

- DIN 471 rings for shafts

- DIN 472 rings for bores

- DIN 983 AK-type rings for shafts

- DIN 984 JK-type rings for bore

- DIN 6799 retaining rings

- DIN 5417 SP-type circlips for grooved ball bearings

- DIN 988 shim washers

- assembly pliers

- etc.