Blind rivet nuts

Company Dejond was formed in 1901 in Belgium has been producing Tubtara blind rivet nuts since 1954. In the middle of 60s Dejond was the first in Europe who started to change manufacturing process of rivet nuts to cold forming from screw machining. Quality of product is ensured by ISO 9001 certification.

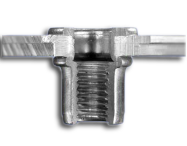

Tubtara® blind rivet nut ensures load bearing thread in thin sheets or in application where there is no or little access at the rear side. It not only used as a nut for a screw, but also to clench separate sheets together therefore acting as a river as well. Tubtara® has to be placed into appropriate sized hole and install with rivet nut tool. Mandrel of the tool pulls the insert lengthwise which cause body to expand on the underside of the workpiece to clench it tightly.

Due to the continuous development the range of Tubtara rivet nuts grow continuously, new designs, new sizes new materials appear. Unique type of Tubtara rivet nuts are made from 316 stainless steel material which can be used in highly corrosive environment.

Benefits:

- Simple blind (one sided) installation

- Provides strong secured thread in a thin sheet

- Fast assembly time

- Avoids damaging the surface

- No deformation of the workpiece

Sizes:

- M3 - M12

Grip range:

- 0.5 - 8.0mm

Body design:

- round, splined round, hexagonal, semi-hexagonal shanks

- open ended, closed ended

- flat, countersunk, low profile heads

Materials:

- aluminium

- steel, Zinktop finish (yellow chromated also available on request)

- stainless steel 304

- stainless steel 316

Blind rivet nuts can be used in wide range of industrial segments and applications such as food industry, pharmaceutical and chemical industry, electronic equipments, medical equipments, telecommunication, metal furniture, automotive industry, ships and boats, aerospace, mass transit vehicles, lighting equipments, power plants, etc.